Transforming Discarded Plastics into Premium Furniture Components with Precision and Purpose.

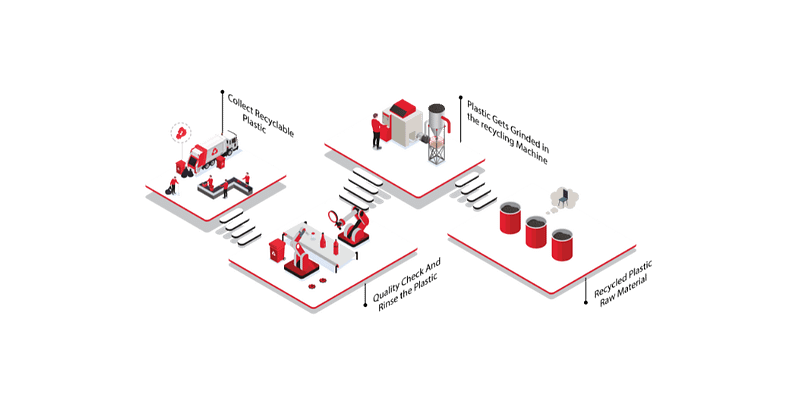

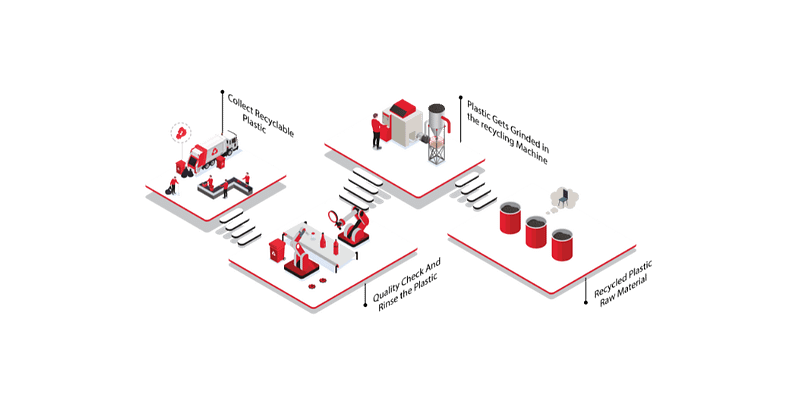

At the very beginning of our sustainable journey, we focus on gathering recyclable plastic materials. This involves sourcing discarded plastic items from various channels, ensuring that they are diverted from landfills and given a new purpose. Our collection process is meticulous, ensuring that we obtain a wide variety of plastic types suitable for recycling.

Once collected, every piece of plastic undergoes a rigorous quality check. This step is crucial to ensure that only suitable materials proceed to the next stage. After inspection, the plastic items are thoroughly rinsed to remove any contaminants, residues, or foreign materials, ensuring a clean and pure recycling process.

After cleaning, the plastic is introduced to our advanced recycling machines. Here, they are grinded down into smaller pieces, breaking them down to their core elements. This grinding process is optimized to ensure that the integrity of the plastic is maintained, making it ideal for its next life in new products.

Post-grinding, the now-recycled plastic material is carefully packed and prepared for its next journey. This raw material, rich in quality and sustainability, is ready to be transformed into new products, completing its cycle from discarded item to valuable resource.

At ScanCastor, our commitment to sustainability is more than just a statement; it's a practice embedded in our production process. Through our innovative approach, discarded plastics are given a renewed purpose, meticulously transformed into high-quality furniture components. This not only reflects our dedication to environmental responsibility but also showcases our ability to merge eco-consciousness with top-tier manufacturing. By choosing ScanCastor's recycled materials, clients are not only investing in superior products but also contributing to a greener, more sustainable future for the furniture industry.

From a mere idea to a market-ready chair, see how we transformed a client's vision into a tangible, sellable product.

We offer Injection Moulding for the furniture industry and we have extensive knowledge in how to incorporate sustainability into your furniture production. Click the icon to read more.

Furniture solutions for the global market.

Copyright © 2024 ScanCastor A / S | All Rights Reserved.